Level transmitters are essential measurement devices used in various industries to monitor level of liquids and fluids in natural water bodies, open channels, tanks,wells and other containers. The choice of a level transmitter usually depends on specific application, properties of the material being measured and mounting location. Various types of level measuring instruments have different installation positions due to their own operating principles. Let’s explore some common types of level transmitters focusing on their differences in mounting locations on process systems.

Immersion type Hydrostatic Level Transmitter

Immersion type level transmitters are designed to be submerged directly in the measuring liquid. These devices typically consist of a sensing element that is placed at a specific depth within tank or vessel. These submersible transmitters are usually inserted vertically into target fluid from top of the container, with the sensing prone placed at the bottom converting exerted hydrostatic pressure to level reading. They can be installed through flange, clamp or a threaded connection. Fixtures can even be dispensed with if the process is structurally feasible, allowing for easy maintenance and replacement.

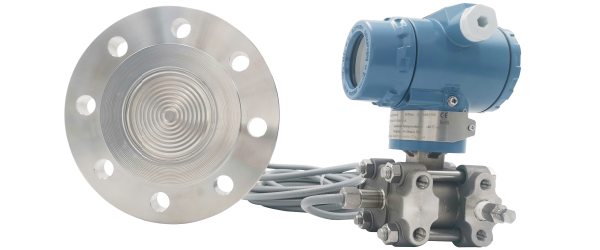

Pressure & Differential Pressure Based Level Transmitter

Pressure-based level transmitters also measure the hydrostatic pressure exerted by the liquid column above the sensor. More specifically, gauge pressure sensor is suitable for open containers while sealed tanks require DP sensor. Pressure-based level transmitters are typically side mounted on the wall of process vessel. Both direct flange mounting and remote capillaries that connect to the transmitter body located away from process are favorable connection approaches. This flexibility allows for installation in tight spaces or hazardous environments.

Ultrasonic Level Transmitter

Ultrasonic level transmitters use sound waves for detection of distance to the level or surface. These non-contact instruments emit ultrasonic pulses that travel to medium surface and then come back, measuring the time it takes for the echo to return to determine the level.Ultrasonic devices are usually mounted right above tank. A clear path for waves to medium surface is essential so that the instrument is suitable for open tanks vessels free from obstructions, vapor, foam or dust.

Radar Level Transmitter

Radar level transmitters operate similarly to ultrasonic transmitters but utilize radar wave signals to measure the distance to the surface. The radar non-contact approach is highly accurate and more universal, can be used in various conditions, including those with vapor, dust, or foam that may interfere with other measurement methods. Similar to ultrasonic products, Radar transmitters are typically mounted at the top of tank where they can send and receive radar signals unobstructed. The top-mounted configuration is advantageous for large containers, as it minimizes the risk of damage from the contents inside.

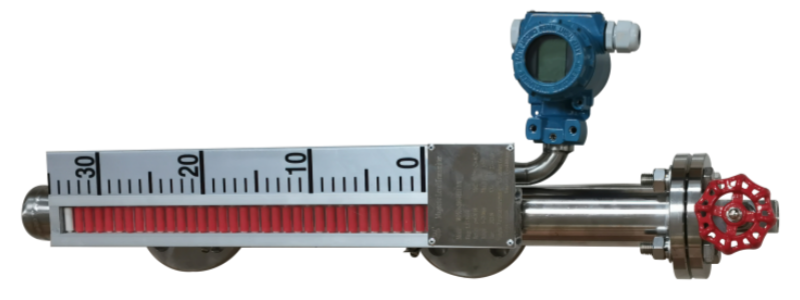

Magnetic Level Gauge

Magnetic level gauges utilize float with magnet that moves up and down along with the liquid level. Magnetic flaps of the field indication panel would flip around between white and red in response through magnetic coupling. The red-white junction of the indicator would be actual height of medium level, providing a legible reading. These gauges are typically mounted vertically along the side of tank via high and low ports, with the float moving inside the guide tube. The configuration provides legible readings and ensures easy installation and maintenance.

Float type Level Gauge

Float ball is another simple yet effective method for measuring liquid level. Integrated buoyant float rises and falls with the liquid level, and its position can be converted into an electrical signal. Float ball transmitters can be mounted in various orientations, including vertically or horizontally, depending on the design of the float and the tank. They are commonly used for medium with suitable density in smaller tanks or applications where simplicity and cost-effectiveness are priorities.

Each type of level transmitter could varies in installation and specification, and has its own advantages and limitations, making it essential to be familiar with them and make decision in the context of actual operating condition. The appropriate selection fortifying accurate and reliable level measurement would ultimately contribute to operational efficiency and safety. Feel free to consult Shanghai Wangyuan with your questions and needs on process level measurement.

Post time: Dec-25-2024