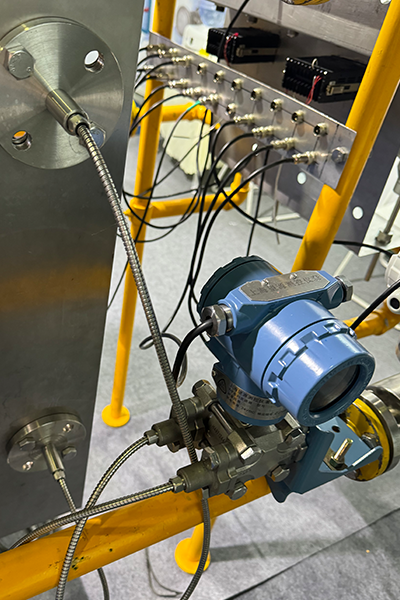

Industrial capillary connection refers to use of capillary tubes filled with specialized fluids (silicone oil, etc.) to transmit process variable signal from process tapping point to device in a distance. The capillary tube is a narrow, flexible tube that connects the sensing element to instrument. With the approach, separation can be made between the body of measuring instrument and process wetted-part. This connection measure is widely introduced in process controls to protect devices from harsh environments, making sure reliable and safe data acquisition. Moreover, such remote installation could also serve as radiation element for extreme temperature use and take readings at more convenient position as per demand of distant reading access.

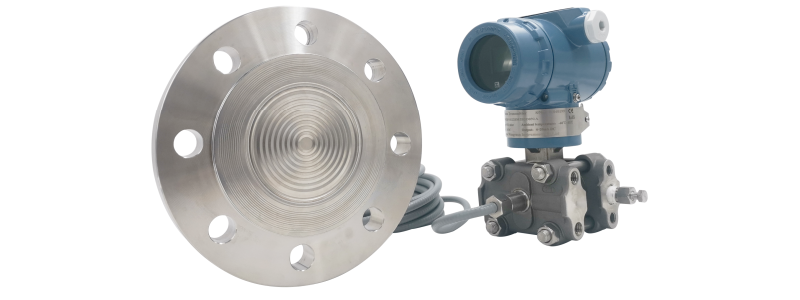

Capillary systems are usually integrated to pressure, level, and temperature transmitters, particularly in applications involving extreme temperature, corrosive medium, or hygienic requirement. In pressure measurement on high-viscosity fluid and aggressive chemical, use of diaphragm seal with capillary connection can protect sensing components from direct exposure to aggressive process medium. For hydrostatic pressure-based level monitoring through, capillary connection enables remote installation of transmitter away from objective storage vessel, minimizing risk of leakage and simplifying maintenance in hazardous sites. While less commonly applied, for temperature measuring instruments capillary tubes are also one of effective cooling measures to protect electronics from direct heat sources, enhancing instrument durability among applications like industrial furnaces and reactors.

Major advantages of capillary connection are the protection of instrument integrity from hostile operating condition and improved reading accessibility and personnel safety. On the other hand, longer capillary length might bring about delayed response time and affect accuracy. Therefore, under the premise of meeting on-site condition, the capillary length ought to be designed as short as possible to guarantee optimum instrument performance. When planning installation, intense vibration and mechanical stress should be avoided preventing tube damage or rupture. Regular capillary inspections for leak and blockage also contribute to instrument service life.

Instrumental capillary connections bridge the gap between industrial process demands and measurement reliability by enabling safe, accurate, and durable signal transmission. Shanghai Wangyuan is an instrumentation manufacturer specializing in process control solutions with extensive experience in capillary connection products. If you have any questions about remote capillary instrumentation, please do not hesitate to contact us.

Post time: Feb-20-2025