What Diaphragm Seal is?

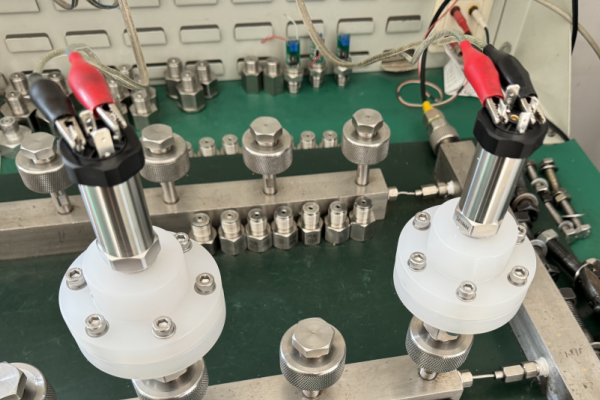

Diaphragm seal is a mechanical device for separation between the measuring instrument and target process medium. Its main part is a thin and flexible membrane (the diaphragm) that responds to pressure changes in the medium through displacement. When pressure is exerted on the diaphragm, it deflects and transmits the pressure by fill fluid to the sensing element of instrument, where such mechanical movement would be subsequently reflected on readable dial or converted into an analog signal.

Why Use Diaphragm Seal upon Instruments?

Protection against miscellaneous conditions: One of major reasons for adopting diaphragm seal is to protect the pressure sensing element from harsh process conditions. In many industrial applications, the process fluid can be corrosive, viscous, toxic, erosive or contain particulates that could damage the gauge or transmitter. Diaphragm seal could act as a barrier preventing harmful substances from coming into direct contact with sensitive components of the instrument.

Improved accuracy and reliability: By isolating sensing element from target medium, diaphragm seal helps maintain the accuracy and reliability of pressure measurement. Potential risk of clogging and fouling could be minimized who is likely to cause erroneous readings. In addition, expanded wetted surface of diaphragm would enhance performance particularly among small range span.

High adaptability: Diaphragm seal can be used in a variety of applications requiring high-pressure and high-temperature environments. Constructed by appropriate material, the diaphragm can accommodate various types of process fluids and operate in a hygienic manner, making it a versatile solution across industries, including chemical, pharmaceutical and food & beverage.

Ease of Maintenance: Instrument equipped with diaphragm seal often demands less maintenance. Since the diaphragm acts as a protective barrier, the sensing element is less likely to become contaminated or damaged, reducing the need for frequent down time, depot repair and replacement.

Considerations for Diaphragm Seal Application

While diaphragm seals offer numerous advantages, there are several factors to consider when using them in pressure measurement applications:

Material: Diaphragm material must be carefully selected based on properties of the process medium. Compatibility with the fluid is essential to prevent degradation or failure of the component. Additionally, the material should be able to withstand the temperature and pressure conditions of the operation.

Sizing: Dimension of the diaphragm and the volume of the fill fluid (the fluid that transmits pressure from the diaphragm to the sensing element) must be appropriate for the application. Incorrectly sized diaphragm structure may prevent installation or lead to measurement errors and slow response times.

Fill Fluid: The fill fluid used in the diaphragm seal must also be compatible with diaphragm material, process medium and operating temperature. Common fill fluids include various kinds of silicone oil. The choice of fill fluid can affect the performance of the pressure gauge or transmitter, including response time and temperature compensation.

Installation: Proper installation of diaphragm seals is essential to ensure optimal performance. Remote capillary connection is feasible catering for specific condition. Regular maintenance checks should be performed to make sure that the diaphragm seal remains in good condition and there is no sign of wear or damage.

Understanding function and role of diaphragm seals will help engineers and technicians make informed decisions on pressure measurement systems, ultimately leading to improved process control and safety. Shanghai Wangyuan is an experienced instrumentation manufacturer specializing in process control solutions. Should you have any queries regarding diaphragm sealed products, please do not hesitate to get in touch.

Post time: Dec-23-2024