From oil & gas to chemical, from food & beverage to pharmaceutical and from iron & steel to plastic, pressure measurement could serve a crucial role in process control across industries to promote quality of product or service and ensure safety and heath. In pursuing suitability of instrument, there would be several technical terms and parameters need to be focused on.

The accuracy class of pressure transmitter is generally represented as percentage full span or scale (%FS). When accuracy grade is consistent and reading value is the same, the reading given by the sensor of larger measurement span is actually with greater error. Seeking top accuracy level could mean excessive high product cost and extended long lead time for more calibration and commissioning to ensure quality. Therefore to exactly cater for the practical demand, it should be noted to choose suitable measuring scale with reference to common & maximum working pressure, and accuracy grade that adequate for actual needs , instead of the higher the better.

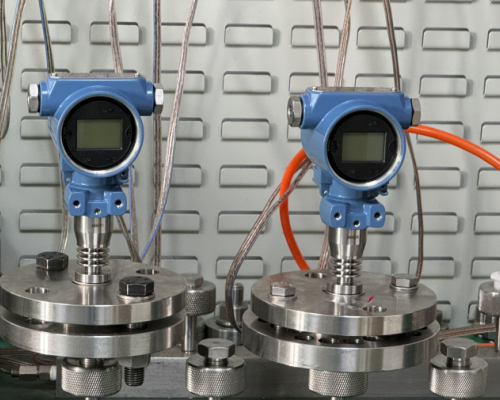

Basic error, hysteresis error and repeatability can be the major indicators reflecting transducer performance in calibration. In a nutshell, hysteresis error capture the discrepancy between results of the same measuring point where applied pressure approaches from both upper and lower directions, while repeatability refers to the span of results among repetitive tests in the same condition. To secure product reliability, test results of these indicators should fall within permissible limits. Linearity describes fitting degree between curve of output-input relationship and theoretical one. It can be improved by ex-factory temperature compensation.

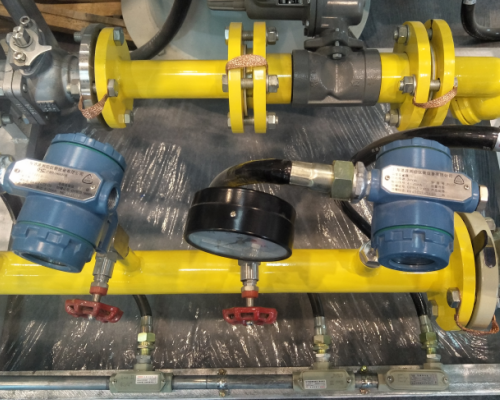

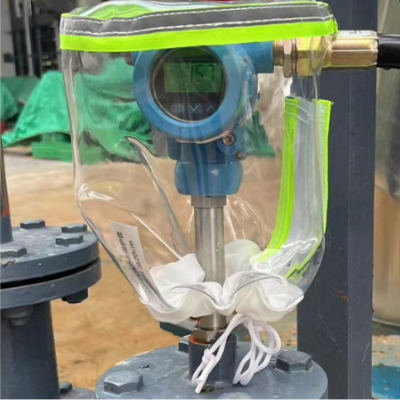

In order to ensure long-term stable and safe operation, contingent potential risk from both external ambience and internal condition require proper preventive considerations in advance. Besides fundamental demands of robust, reliable structure and housing, ex-proof design, waterproof cover or anti-corrosion casing might be necessary in a variety kinds of harsh operating condition. Aggressive or viscous measuring media could request specific anti-corrosive materials or remote connection approaches in response. Overload or static pressure protection are indispensable when expecting great pressure fluctuation. Limits on weight and size can also be major consideration on certain applications, where compact type transmitters would be most preferable simplifying start-up and maintenance.

Shanghai Wangyuan has been engaged in manufacture and supply of pressure transmitters for over the decades. Our Field-proven cases and ample expertise enable us to deliver proper and reliable process control solutions on timely basis exhibiting versatility on product customization. When you feel confused about instrument selection for the factory conditions, please don’t hesitate to contact us.

Post time: Nov-27-2024