Temperature measurement is a critical aspect of process control across broad variety of industries such as chemical manufacturing, oil and gas, pharmaceuticals, and food production. Temperature sensor is a essential device that directly measures thermal energy and translate temperature movement into electrical signals to achieve continuous monitoring and data collection on whether a process is functioning within defined temperature scope. As mentioned in Can We Replace RTD with Thermocouple?, common temperature sensing elements include RTD and TR, who are excel in different measuring span and output ohm/mV signal separately.

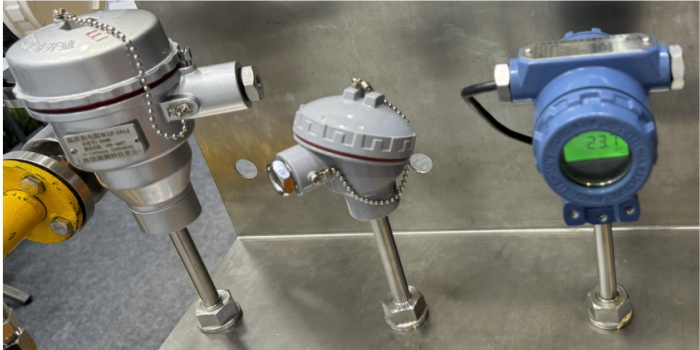

While temperature sensor has long served as the fundamental device for capturing thermal data standalone, it can be integrated to transmitter systems in process control applications. Temperature transmitter is an intermediary device that connects to RTD or thermocouple sensor, amplifies and conditioned sensor signal to standardized electrical signal, then outputs to receiving electronics. The conditioned signals read for use by back-end control system like PLC or DCS are usually analog 4-20mA and digital Hart or Modbus communication.

Advantages of applying temperature transmitter

While temperature sensors remain fundamental for data acquisition, transmitters elevate their utility by several improvements:

Enhanced signal integrity: The trivial voltage signal in the circuit produced by temperature sensor alone is weak and susceptible to electrical noise and interference as well as signal degradation over long distance. In comparison, 4-20mA signal regulated by transmitter is more robust and facilitates resistance to electromagnetic interference. Linearization and compensation for raw sensor output make data transmission towards the control device more accurate and reliable.

Compatibility & convenience: Temperature transmitter module is compatible with to both RTD and thermocouple sensors. Employ of multiple sensing elements can be also acceptable. The versatility enables transmitter to be widely applied to all kinds of temperature measurement with different span and sensor quantity requirements. On-site indicator can be placed on terminal box providing convenient legible local reading and configuration.

Improved system integration: Standardized transmitter output facilitates seamless integration with control systems like programmable logic controller (PLC) and distributed control system (DCS). Digital communication enables remote real-time data monitoring and parameter adjustment, minimizing need for physical access to hazardous or hard-to-reach locations. Field recalibration through digital interface is simplified and reduces downtime compared to manual operation.

Shanghai Wangyuan has been engaged in manufacturing and service of measurement instrumentation for over 20 years. Our extensive professional knowledge and field experience allows us to provide temperature control solutions exactly meet your needs. If there is any questions and demands regarding temperature sensor and transmitter, please do not hesitate to contact us.

Post time: Mar-24-2025