Heat sinks are often used in electronic devices to dissipate heat energy away, cooling down the devices to moderate temperature. Heat sink fins are made of heat conductive metals and applied on high temperature device absorbing its heat energy and then emit to ambience via radiation and convection. Though the most common daily application of heat sink which might come into our minds only is on the CPU of personal computer along with fan and thermal paste, it is also proven to be useful in dealing with overheat process medium of instrumental device.

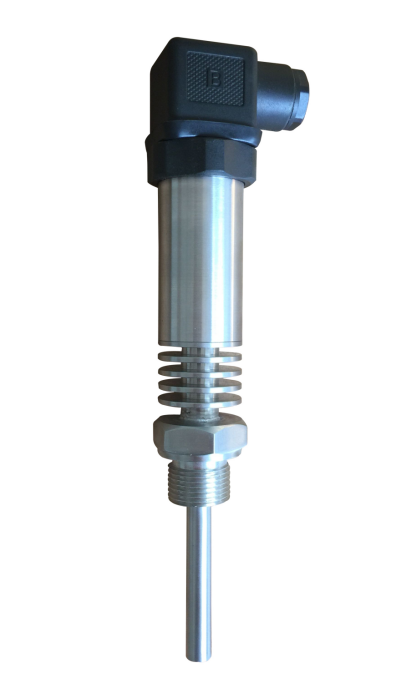

Ideally speaking, it is best to install a transmitter as close to process as possible to secure quick dynamic response. However, in high medium temperature industrial processes, transmission of heat could impair and shorten lifetime of wetted-part and circuit components. Protective measures should be taken into consideration when medium process temperature would rise above 80℃. One practical and reliable approach for pressure transmitter without undermining response time to guard upper circuit board is to attach several heat sink fins between wetted process and terminal block. Regarding to Temperature measuring device, general choice is to extend upper stem to protect electronic parts from overheating. But structure welded cooling fins is also a feasible option.

As a professional instrumentation manufacturer, WangYuan certainly won’t neglect to seek solution for high medium temperature issue. Adopting heat sink construct, Our WP421 series pressure transmitters are specially designed to improve maximum operating temperature. Similar anti-heat measures are also shown on sanitary WP435 series and temperature products. Feel free to contact us if you have any further question or requirement on high temperature process control.

Post time: May-13-2024